Abrasive Cleaning

At OAK linings our surface preparation can take the form of chemical or mechanical methods depending on the situation we are confronted with and the type of substrate.

Our Abrasive cleaning and surface preparation methods use very efficient and environmentally- friendly methodology. Proper substrate and surface preparation is vital in the coating industry. Most coating failures can be attributed to bad or insufficient substrate preparation. Our surface preparation ensures the best-possible mechanical bonding and adhesion, while also helping to mitigate later problems, such as corrosion and mechanical damage.

Every project or challenge is unique therefore there is not one method that fits all. At OAK linings our surface preparation can take the form of chemical or mechanical methods depending on the situation we are confronted with and the type of substrate.

Our mechanical abrasive cleaning methodologies including

- Power Tools

- Grit Blasting

- Vapor Blasting

- Wet Blasting

- Hydro Blasting

- Shot Blasting

- Diamond Disc Grinding

- Scarification

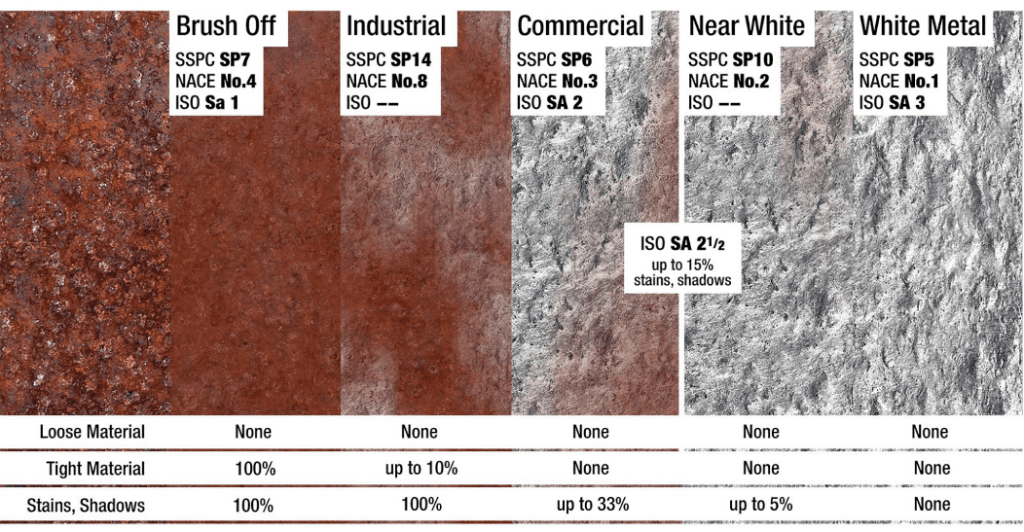

We conform to ISO, SSPC-SP, and NACE standards with all our surface preparation.

1. Light Blast Cleaning / Sweep Blast Cleaning / Brush Off

2. Industrial Blast Cleaning

3. Commercial Blast Cleaning

4. Near White Blast Cleaning

5. White Metal Blast Cleaning